Surface preparation is the essential first stage treatment of a material substrate before the application of any coating, and is generally accepted as being the most important factor affecting the total success of a corrosion protection system.

High-pressure surface preparation is not only economical, but with so many environmental advantages it is swiftly becoming the preferred process for coating removal by many major industries. High Pressure technology delivers the power to clean the most difficult surfaces down to white metal quickly and cost effectively using a minimum amount of water.

Spiderjet

Spider jet

Spiderjet

Spider jet is a semi-automatic device used in shipping industries for surface preparation using ultra high pressure up to 3000 bar.

-

- This unit can be used for stripping vertical inclined and horizontal surfaces.

- The Spider jet attaches to the work surface by vacuum force at is driven by a pneumatic motors.

- The vacuum also retrieves all waste water and removed solids.

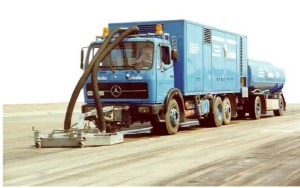

RD Flex 3000

This is a high pressure cleaning accessory used in High Pressure Guns for renovation like surface layer removal, Paint removal, concrete removal, expansion joint removal, Paint booth grid & skid clean up, Hull deck and superstructure surface preparation.

- Pressure up to maximum 3000 bar.

- Flow rate up to 30 liters per minute.

- Rotation speed from 1000 to 4000 RPM

FRV-3000

Cleaning equipment used for on deck cleaning, paint booth cleaning and or various other surface preparation using high pressure spray bars.

A vacuum system is attached to this equipment in order to collect the waste water and debris from the surface.

The maximum operating pressure is up to 3000 bar.

Hand aquablast

It is a cleaning device used for

surface preparation using a

vacuum system operated manually.

Cleaning, striping vertical surfaces.

Ship repair- removal of marine growths, stripping hull coatings

Construction Industry: removal of paints and for other concrete surfaces.